|

| Broken Belts from McGuire Bearing |

|

| New Belts from Polybelt.com (grey ones are steel reinforced) |

Building an electric longboard, cause its cool and I'm too old to play with legos.

|

| Broken Belts from McGuire Bearing |

|

| New Belts from Polybelt.com (grey ones are steel reinforced) |

|

| Top View |

|

| Bottom View |

| |

| Side View |

|

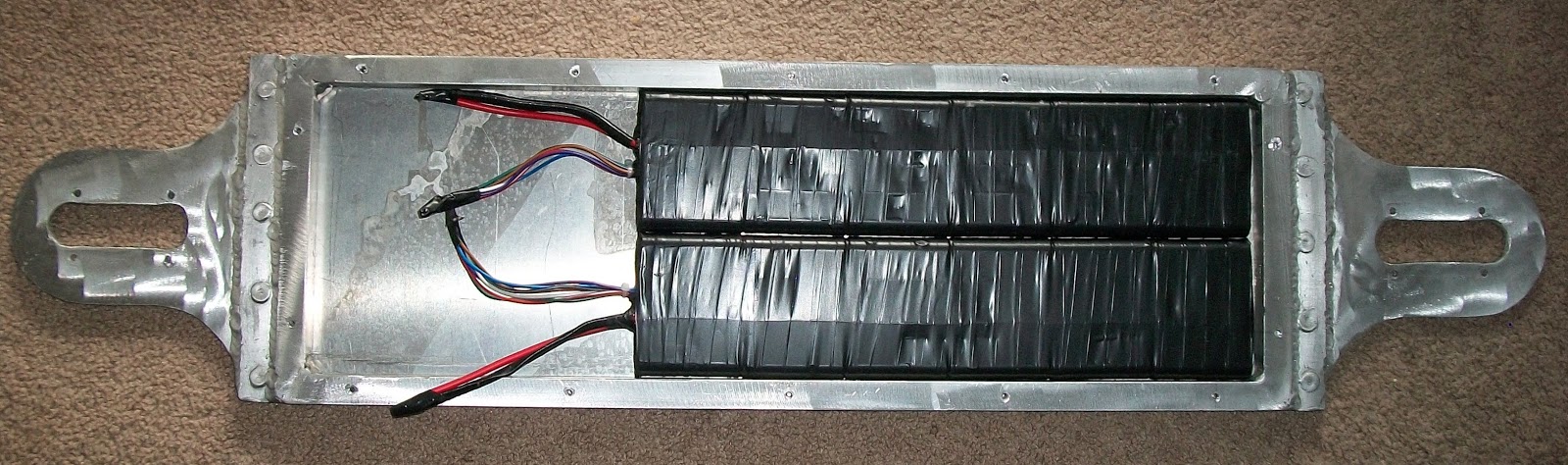

| Fabricated Charge Balance Splitter |

|

| Added DC Power Connector and Balance Connector (left middle) |

|

| Charger hooked up to the DC connector and balance connector |

|

| Charger/Power Adapter/Remote |

|

| Bottom of Longboard without cover plate |

| |

| Bottom of Longboard with Plate (drive end) |

|

| Bottom of Longboard with Plate off (drive end) |

|

| Wiring/Receiver/Etc |

|

| Added Bullet Connectors and JST-XH Connectors to Battery Packs |

|

| Added Bullet Connectors to the Motor Controllers |

|

| 5.5mm Gold Plated Bullet Connectors |

|

| Parts - Pulleys/Washers/Bolts/Belt |

|

| Parts Bolted to the Wheels |

|

| Parts Bolted to the Wheels (alt view) |

|

| Wheels and Motor connected together on the trucks |

|

| Wheels and Motor connected together on the trucks (alt view) |

| |

| Small XL (1/5 Pitch) Pulley - 10 Tooth |

|

| 9" XL (1/5 Pitch) Pulley - 45 Tooth |

| |

| Large XL (1/5 Pitch) Pulley - 30 Tooth |

|

| Motor Mounts |

|

| Motor Mounts (alt view) |

|

| Mounts with the Motors on them |

|

| Mounts with Motors on the Trucks |

|

| Mounts with Motors on the Trucks (alt view) |

|

| 50mm Brushless Outrunner Motor |

|

| 3D Rendering Wire Frame |

|

| 3D Rendering |

|

| One Side |

|

| The Other Side |

| |

| Finished pack wrapped in electrical tape but no connectors. |

|

| Battery pack in the board. Fits well. |

|

| Top |

|

| Top (alt view) |

|

| Bottom |

|

| Bottom (alt view) |

| |

| Top with Top Plate |

|

| Top with Top Plate (alt view) |

| |

| Bottom with Bottom Plate |

|

| Bottom with Bottom Plate (alt view) |